Introduction

Live-Training

Lean and TPM practitioners Fall 2025

Seven-day certificate training course for lean multipliers and TPM experts,

who are taking on a new role in the practical implementation of lean management.

Lean continues to be considered the foundation for many of the new challenges in our factories! But how can we ensure that once Lean successes have been achieved, they are established on a sustainable basis? And how can we introduce new and young employees to these proven methods?

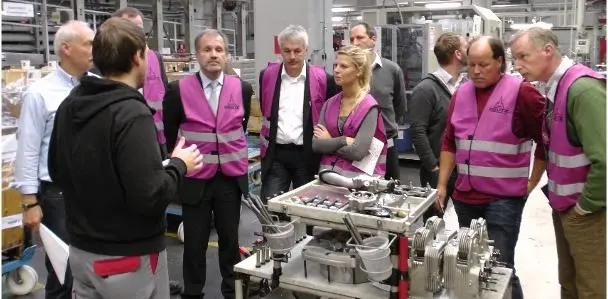

This training takes place in cooperation with three organizing companies. For many years, these companies have been developing successful multiplication and training concepts in a network with the best lean implementations in Germany, thus ensuring sustainability in their own plants. Looking beyond the horizon and exchanging ideas across companies is a decisive factor for success.

All modules take place live in factories in a practical setting.

Start of training at Wieland-Werke AG in Villingen as a best practice example (TPM Factory of the Year)

Based on proven lean principles and tools

Ready to take on the role of lean multiplier in your factory?

Seven-day, practical training in three blocks:

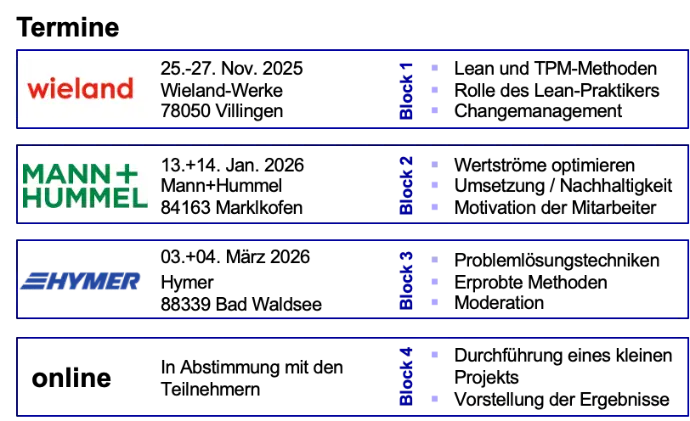

Dates:

Participation costs: 2,950 euros plus statutory value added tax

Special features of this live training:

- The training program was developed in a practical manner within a group of successful TPM and lean companies and has been running successfully for over 10 years.

- Start of training at Wieland in the Villingen plant, one of the best TPM factories.

- All modules take place live in companies, ensuring a direct link to practical application.

- Lean methods training is combined with training in application skills (moderation, problem-solving skills, social skills, etc.).

- Access to many best practice examples.

- Option to implement your own project in parallel and present it in a digital thesis.

Target group:

- Selected new multipliers, trainers, and moderators.

- Experienced practitioners who take on a new role in CIP.

- Future supporters of the improvement process.

- Prospective CIP coordinators and process facilitators, new project managers, Kaizen managers.

In this 7-day training course, you will learn:

- The basic lean methods and tools.

- Understanding your role and success factors as a multiplier.

- Successfully planning, managing, and securing improvements and workshops.

- Lively moderation and interaction techniques in a team.

-

Sicheren Umgang mit Konflikten.

- The fundamentals for ensuring sustainable results.

Block 1 at Wieland-Werke AG:

Day 1 - 25.11.2025

TPM at Wieland: Insights into practice with many live stations

- Basic idea of Lean & TPM

- TPM implementation live on equipment

- OEE recording and optimization

- The role of maintenance as a partner

- Standards in optimization

- Involvement of employees in the change process

- Establishment of a TPM/Lean system

- Understanding Lean Principles

- The role of the lean practitioner

Day 2 - 26.11.2025

Method overview of Lean and TPM

- TPM pillar model

- Autonomous maintenance

- Planned maintenance

- Recognizing and eliminating center of gravity losses

- 5S as a basis

Day 3- 27.11.2025

The role of the lean practitioner in the change process

- Recognizing, learning about, and overcoming obstacles and resistance

- Professionally supporting change as a change manager

- Successfully implementing CIP methods in your company

- Fundamentals of agile project management and simple SCRUM tools

Block 2

at Mann+Hummel in Marklkofen (Images are archive images and were not taken at Mann+Hummel.)

Day 4 - 13. Jan. 2026

Moderation and communication as a Lean and TPM practitioner

- Basic principles of moderation

- Structure and preparation of a moderation and the role of the moderator

- Moderation techniques and rhetoric. Suggestions for small group moderation, rhetorische Tipps und Kniffe

- Procedure for a group meeting or workshop

Day 5 - 14. Jan. 2026

Solve problems systematically

- Learning to see ... Recognizing potential (chalk circle exercise)

- Problem-solving cycles from problem identification to implementation

- Procedure and visualization when describing the problem

- Procedure and visualization in root cause analysis

- Approach and visualization in finding solutions

- Exercises based on practical examples in the factory

Block 3 at Hymer in Bad Waldsee (Images are archive images and were not taken at Hymer.)

Day 6 - 3. März 2026

Lean and TPM tools for process optimization

- Power equipment as a factor for success

- Analyze value streams and optimize throughput times

- Visualize processes

- Lean in the office – where are the differences?

- Exercises in the factory

Day 7 - 4. März 2026

Motivation and coaching within the team and sustainability in implementation

- Perception, analysis, handling, and resolution of conflicts

- How do I motivate participants in the workshop?

- Coaching in dealing with conflicts

- Sustainability in the CIP process

- Guidelines for a successful audit