Lernreise "Produktion der Zukunft"

2023-2025

Under the patronage of Siemens AG and Fraunhofer IPA

Learning Journey "Production of the future"

2023-2025

Under the patronage of Siemens AG and Fraunhofer IPA

The Resilient Factory

The production of the future must face up to new realities. In an environment of constant crises, flexibility and robustness are more important than ever. And ensuring competitiveness is a major challenge. Achieving more with less is the goal for the coming years. And this is where the innovation drivers of lean, green, and digitalization offer great opportunities.

New Lean – Lean in the 21st century

Imagine if you could combine the flexibility of workshop production with the economic advantages of flow production. Experts call this matrix production and are already referring to it as the lean production method of the 21st century.

Digital – After the compulsory comes the freestyle

No factory can avoid the digital networking of its existing machinery. However, once the foundations have been laid, a whole range of new possibilities opens up, from virtual planning approaches and fully automated logistics systems to unmanned shifts at the weekend.

Green – From a CO2-neutral factory to a sustainable factory

The CO2-neutral factory will be the new standard in just a few years. The focus will then be on topics such as the circular economy and zero-impact factories, i.e., factories with no harmful environmental impact whatsoever.

Project schedule for the learning journey

2023 -2025

17-18.11.2023

With lean, green, digital towards emission-free and loss-free production

Stuttgart

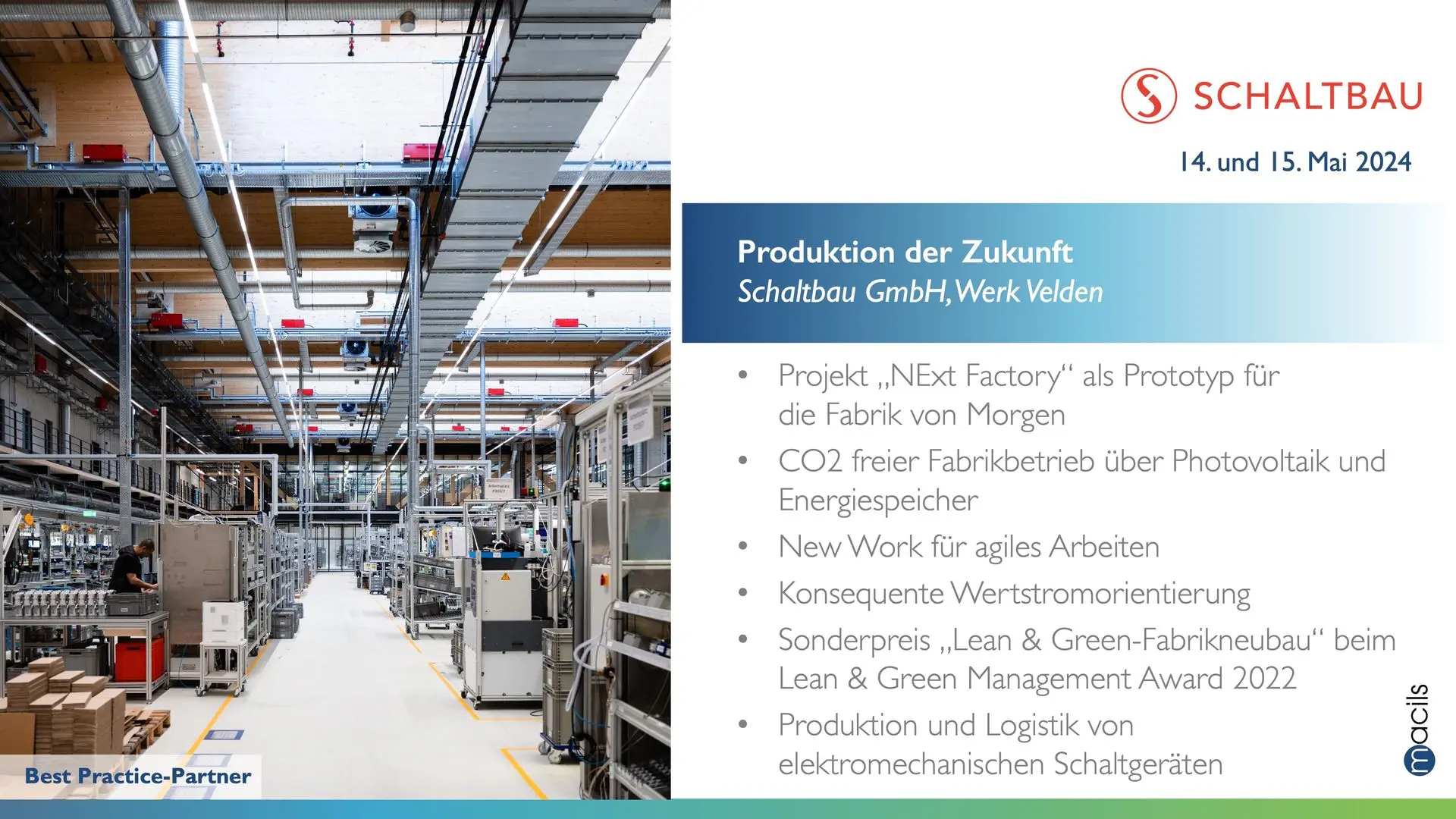

06-07.03.2024

Digitalization turbo and CO2 downsizing

Werk Garching bei München

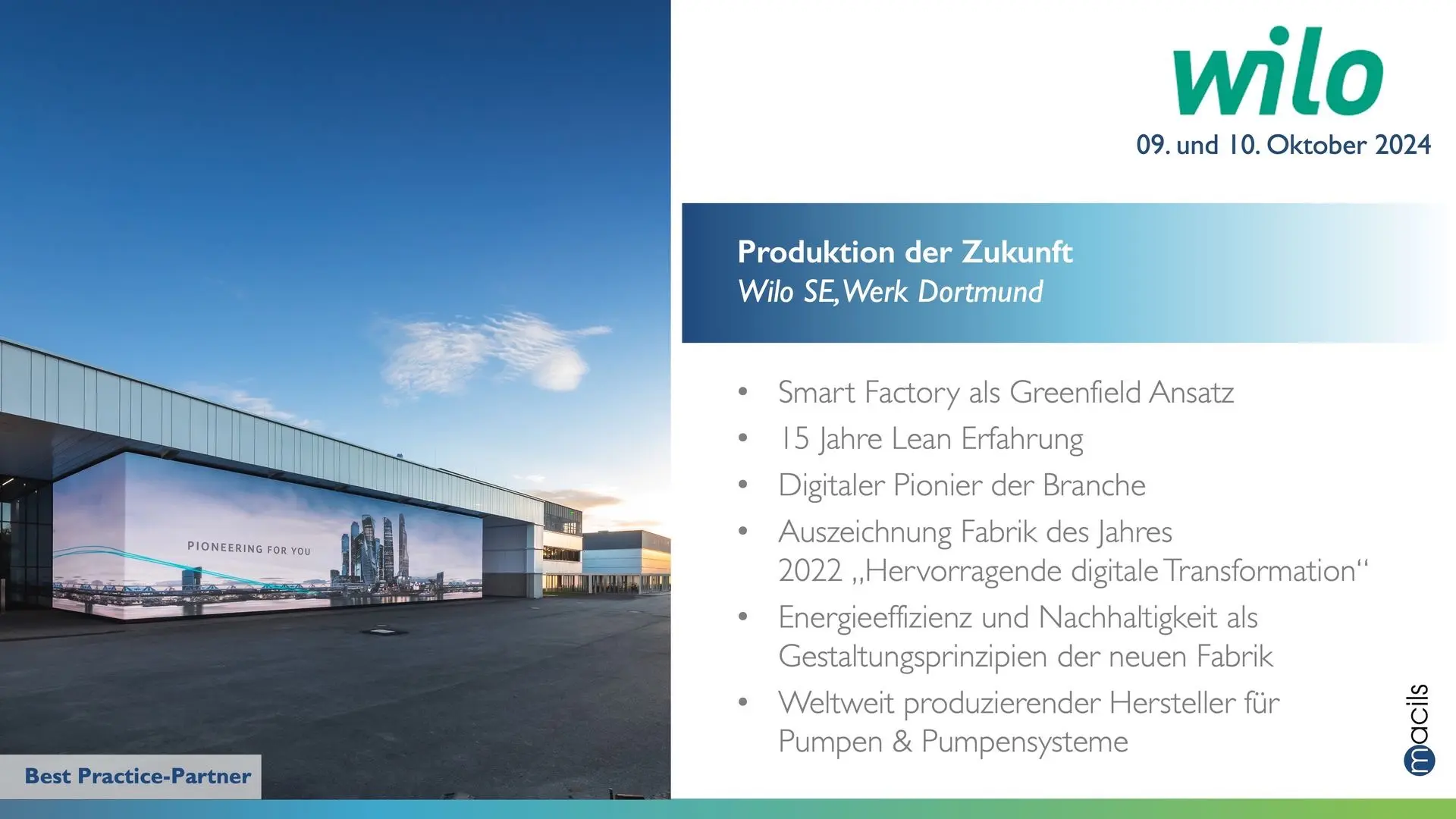

26-27.06.2024

The second generation of a smart factory is launched

Werk Blaichach | Immenstadt

06-07.11.2024

Siemens Appliance Factory Erlangen shares its journey into the industrial metaverse

Werk Erlangen

12-13.02.2025

Smart Factory Bühlertal – Material logistics makes the difference

Werk Bühlertal

With lean, green, digital towards emission-free and loss-free production

Stuttgart

Digitalization turbo and CO2 downsizing

Werk Garching bei München

The second generation of a smart factory is launched

Werk Blaichach | Immenstadt

Siemens Appliance Factory Erlangen shares its journey into the industrial metaverse

Werk Erlangen

Smart Factory Bühlertal – Material logistics makes the difference

Werk Bühlertal

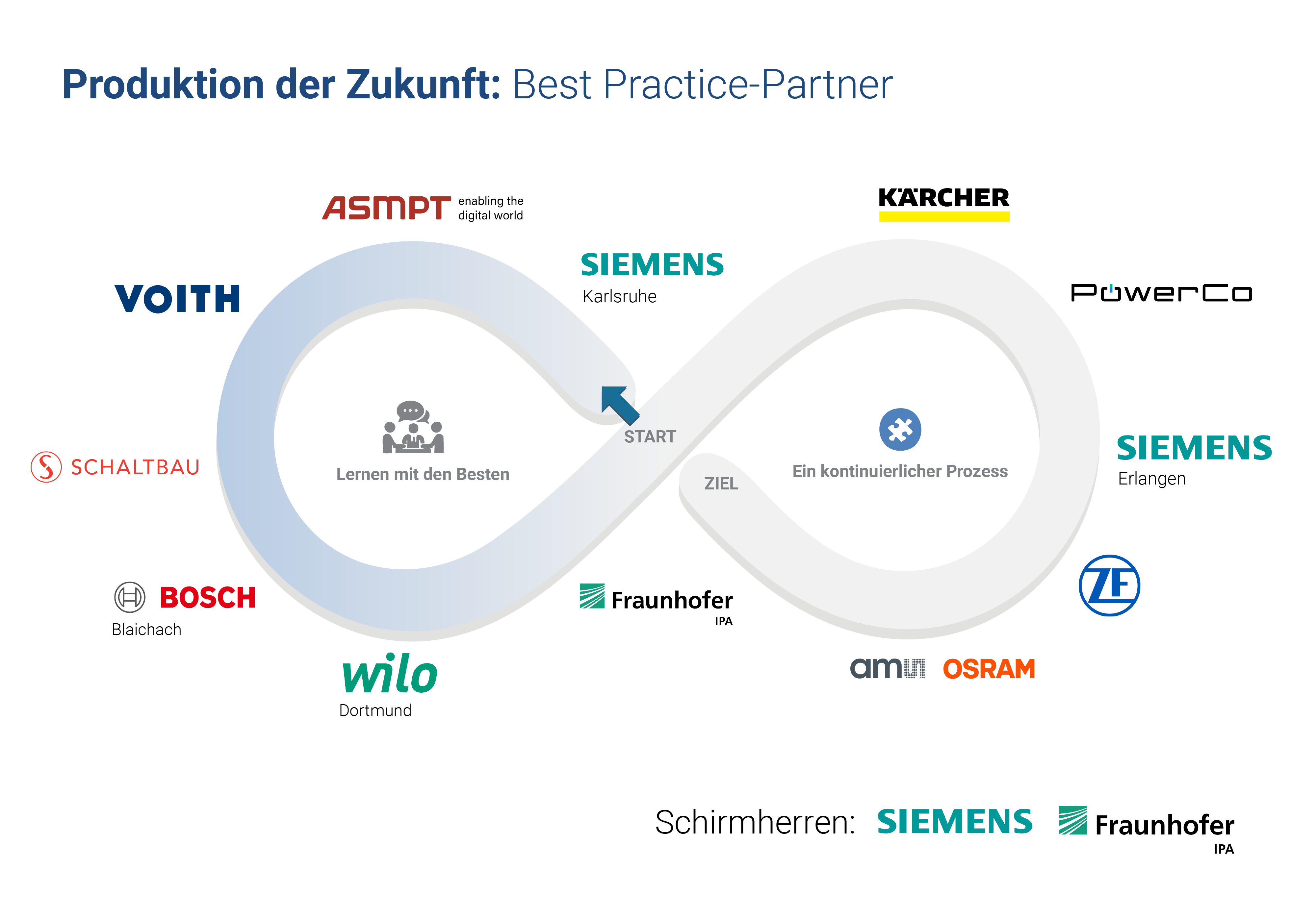

Become part of the learning journey community

Live, on the web or as an app

Participating companies | Impressions of the participants

Angela Balheim

- EVENTS PROJECT MANAGEMENT -

Tel.: 0711 / 737 344 26

E-Mail: angela.balheim@macils.de

Presentation available for download